How Would You Design a Company Around AI?

What Henry Ford's electrification breakthrough teaches us about building with AI from the ground up

I've always heard of Henry Ford as being very influential in the automotive industry, but I always assumed that was because he invented some crucial part of the car. What I came to realize was that his genius wasn't in automotive engineering—it was in figuring out how to manufacture cars cost-effectively, expanding the market and making it possible for everyone to drive.

Ford wasn't first. By the time he started the Ford Motor Company in 1903, there were already dozens of automobile manufacturers across America. Companies like Oldsmobile, Cadillac, and Packard were already building cars. Some were even more advanced than Ford's early models.

Ford was just another struggling automaker trying to figure out how to lower the cost of his cars. In 1908, his Model T took over 12 hours to build and cost $825—expensive for most Americans. Ford knew that if he could drop the cost of construction, his market would grow exponentially.

That's when he had his slaughterhouse moment.

In 1913, Ford visited the Chicago stockyards. As he watched workers move carcasses along overhead trolley systems from station to station, each person completing one specific task, he suddenly had an insight: what if he could reorganize his factory so the work came to people instead of people coming to the work?

The constraint wasn't the workers or the parts—it was the layout. Traditional factories were organized around steam power, with everything connected to a central engine through belts and pulleys. But electricity was a new technology that changed everything. With electric motors, each machine could have its own power source. Ford could redesign his entire factory floor around workflow efficiency, not power distribution.

The results were impressive. By October 1913, Ford's moving assembly line reduced Model T production time from 12 hours and 13 minutes to just 93 minutes. This wasn't just an improvement—it was a complete transformation that let Ford dominate the industry.

I had this realization while reading about Ford's breakthrough, and it hit me: the same transformation is taking place with AI right now. Most companies today are treating AI like those early manufacturers treated electricity—just swapping tools without redesigning workflows. (I've written about this before in The Future of Knowledge Work.)

But just like Ford's assembly line moment, the real opportunity isn't in using better AI tools. It's in building your company around AI from the ground up.

The McDonald's Tennis Court Principle

Ford wasn't the only one to understand this principle. Decades later, the McDonald brothers faced a similar challenge with their restaurant in San Bernardino, California.

In the early 1950s, the brothers were struggling with slow service and inconsistent quality. Their traditional restaurant setup had servers taking orders, cooks preparing meals individually, and a chaotic kitchen where workers bumped into each other trying to complete orders.

Instead of just hiring more staff or buying better equipment, they did something radical: they closed their restaurant for months and redesigned everything from scratch.

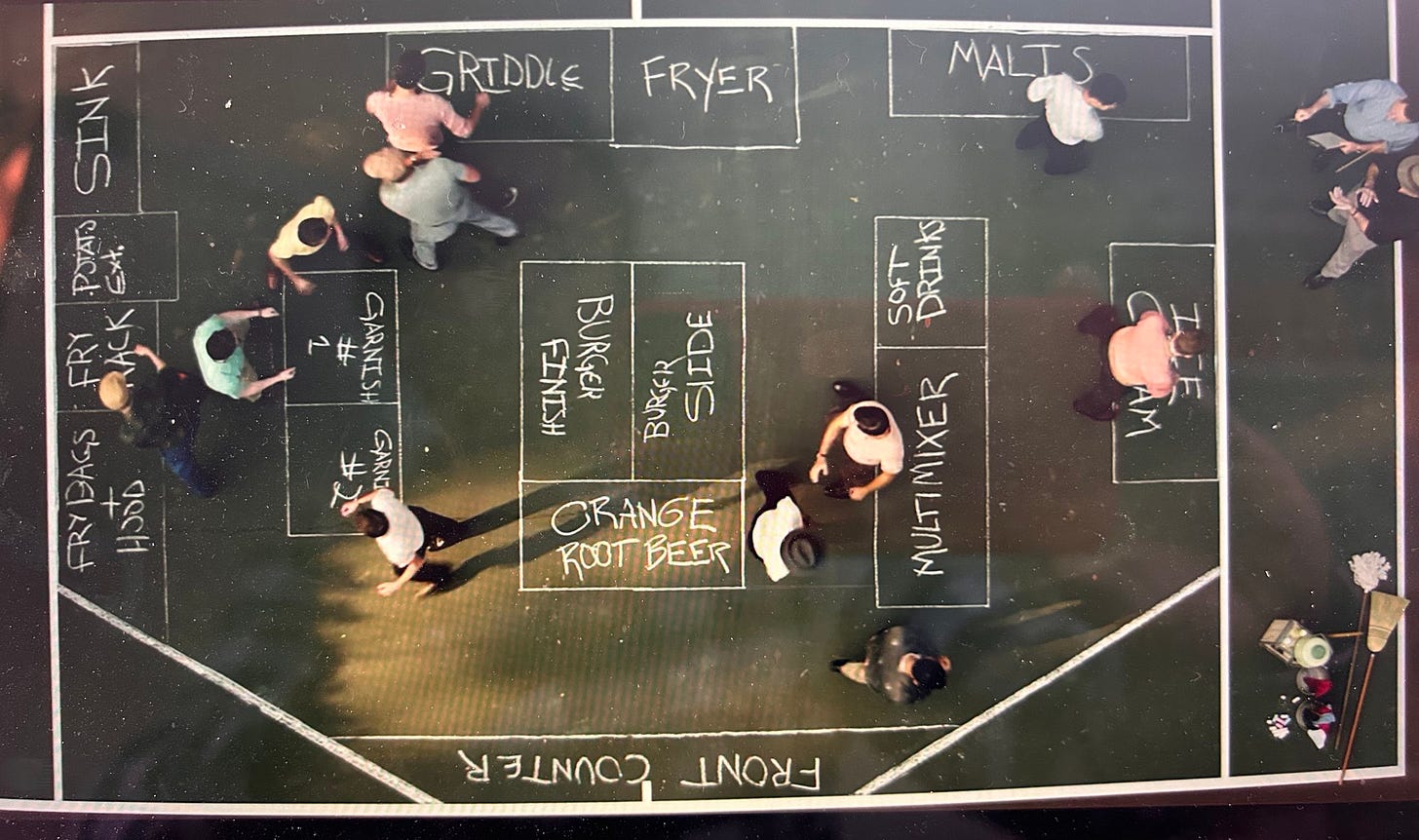

The brothers went to a tennis court, grabbed some chalk, and drew out the exact dimensions of their restaurant. They brought in their staff and asked them to recreate their work—a true example of process choreography. As they watched their employees move around the chalk outlines, they could see the inefficiencies: workers bumping into each other, duplicated tasks, and wasted motion.

Then they started experimenting. They wiped the tennis court clean and redrew the layout, moving prep stations around, focusing each employee on one simple task that could be passed to the next station without delay or confusion. After multiple iterations, they discovered their ideal system—what became known as the Speedee Service System.

Each employee now had one specific task they could repeat quickly and consistently. The end-to-end process could deliver food to customers in 30 seconds instead of 30 minutes. All they had to do was rebuild their physical restaurant to match the tennis court design.

The key insight was the same as Ford's: they abstracted their process from the physical constraints to optimize for what actually mattered—speed and consistency.

My Own Tennis Court Moment

I've been running my own version of this experiment for the past two years with AI-assisted writing. What started as curiosity about AI tools became a deliberate practice in workflow redesign.

Initially, I treated AI like most people do—as a better search engine or a more sophisticated autocomplete. I'd copy-paste text into ChatGPT, get a response, then copy-paste it back into my document.

But over time, I started redesigning my entire writing process around AI capabilities. I moved from standalone chat interfaces to integrated tools like Cline and BoltAI. I developed prompt files and system instructions that gave AI context about my style and preferences. Most importantly, I learned to work alongside AI rather than just asking it to write for me.

The difference is real. Instead of "AI, write this article about Ford," it became a collaborative process: I provide the insights and direction, AI helps with research and structure, I refine and inject my voice, we iterate together. The AI doesn't replace my thinking—it amplifies it.

The lesson from my writing experiment became clear: there's still a lot to figure out about how to work with AI. The thinking that says we can simply swap people for AI misses what people actually do and what AI can actually do. It's like swapping out steam-powered machines for electric ones without redesigning the factory floor.

But if we can learn to orchestrate people and machines the way Ford and the McDonald brothers did, then we can build something transformative.

Building the AI-Native Company

Since the beginning of this year, I've been working on my own metaphorical tennis court. I've been asking myself: what does it look like to build a software company from scratch with AI built-in? The current zeitgeist calls this an "AI-Native" company—like Ford's assembly line.

Picture a typical software startup building an app. The CEO has an idea, writes requirements, hires engineers to code it, designers to make it beautiful, marketers to find customers, and support staff to help users. It's a knowledge assembly line: raw ideas move through human workers who transform them into working software that customers pay for.

Just like Ford's factory, this process has clear stages:

Raw materials: Market insights and product ideas

Assembly line: Engineers, designers, marketers transforming ideas into software

Finished product: Working applications that solve customer problems

Distribution: Marketing and sales getting the product to paying customers

Most companies today are doing what those early manufacturers did with electricity—they're plugging AI tools into existing roles. AI helps engineers code faster, helps marketers write better copy, helps support teams answer questions more efficiently. Same assembly line, better tools.

But what if you redesigned the entire operation around AI capabilities? Imagine a company where the "assembly line" looks completely different: AI handles the routine transformation work, humans handle the judgment calls, and the entire operation is designed around this collaboration from day one.

These are early days. I'm learning constantly and getting things wrong regularly. But the industry has clearly started moving toward this future.

In the coming weeks, I'll be sharing what I've learned from this experiment. If you're interested in how the factory floor is being redesigned for the age of AI, subscribe below.

`